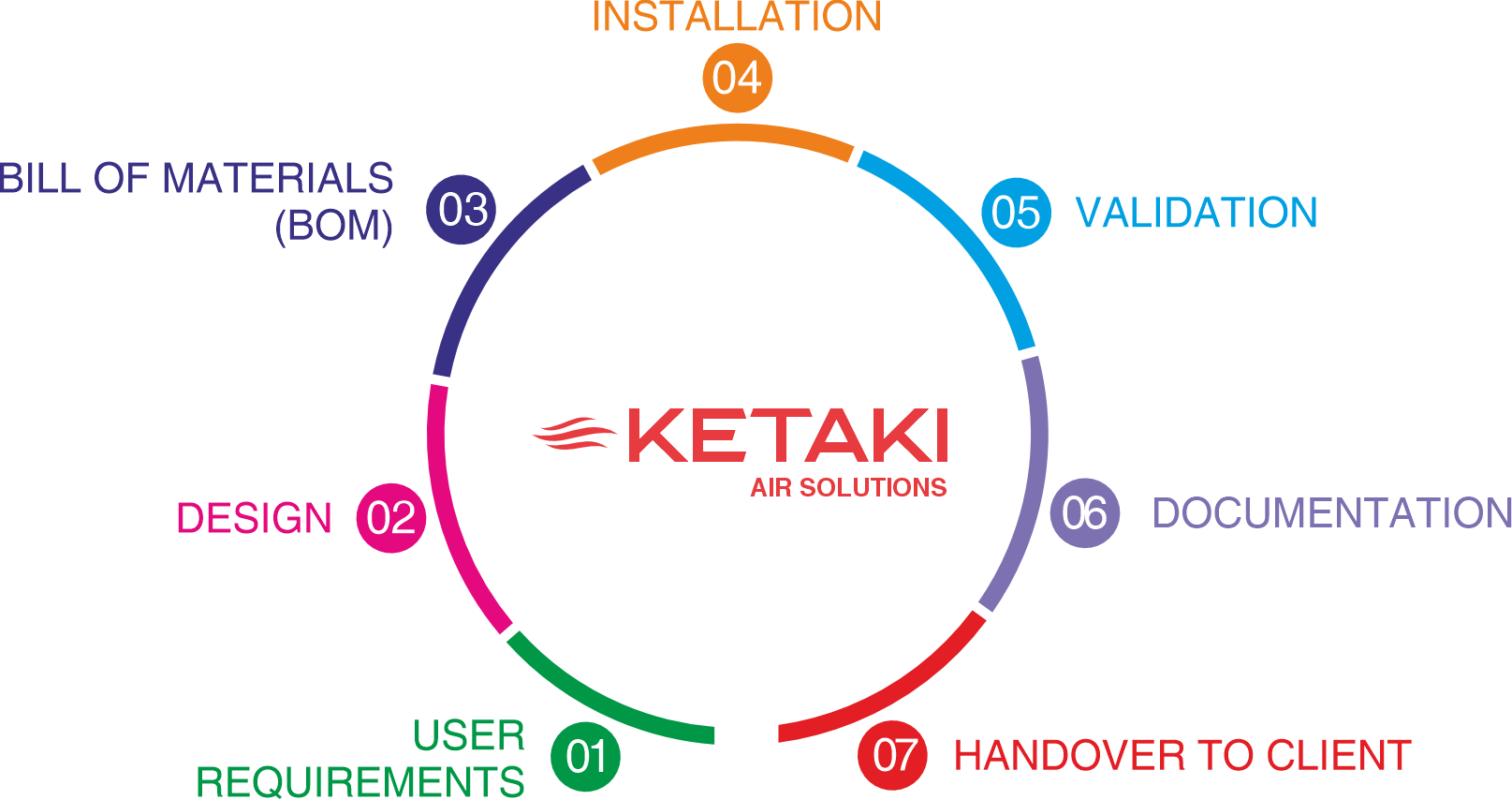

At Ketaki Air Solutions., we collaborate closely with client specifications and user groups to engineer machines and equipment that deliver reproducible results. Our established process generates comprehensive technical documents, including DQ, PQ, IQ, OQ and test certificates, ensuring that SOPs are easy to follow and sustainable. This meticulous approach guarantees that factory acceptance testing (FAT) is done right the first time, providing a fast track to qualification and reliability. As a result, projects meet their timelines, and research and production commitments are fulfilled on schedule.

We provides end-to-end qualifying services for both single-unit and complete turnkey facilities. We begin with risk assessments connected to design qualification and work our way up to important checkpoints like operational qualification, installation qualification, calibration, and testing of alarm functions. Utilizing our relationships in India and other developed nations, we additionally offer cycle development and validation in certain situations to guarantee the greatest caliber of quality control. Working closely with client groups, Ketaki Global facilitates workshops at every level to build a long-lasting relationship between the equipment, the customer, and Team Ketaki.

Ketaki Air Solutions offers practical, long-term solutions by encouraging users to opt for cost-effective, comprehensive annual maintenance contracts (AMC). For special greenfield projects, we also implement operations and maintenance contracts when client groups are not equipped to handle the 24/7 demands of such facilities. Each client group under AMC is assigned a unique number, which can be used to check records and post feedback online.

Ketaki Air Solutions, in collaboration with National company renowned GMP in-house team, has elevated its training initiatives. Our structured programs now cover every aspect of cGMP and cGLP, including on-site modules. We also offer augmented reality and remote training options. Ketaki partners with both international and national experts to provide global skill sets for addressing process and packaging regulatory issues through audits, inspections, and specialized training.

Going beyond regulatory requirements, Ketaki Air Solutions delivers benchmark value-added services, including fully customized risk and threat assessments, I/O testing, leak testing, disaster recovery, and software & SCADA for building automation. We also take on pioneering custom projects that often require unique process development, where our qualification services are tailored to align with the quality by design paradigm, ensuring optimal outcomes.

Providing timely and essential support for such facilities and equipment is crucial. User groups, including operators, principal investigators, production managers, project engineers, and field technicians, often require assistance in overlapping areas of concern. The Ketaki Air Solutions product support team is always ready, continuously trained, and updated on the latest trends, regulations, and future developments. This ensures they offer invaluable assistance to clients and their user groups, meeting their needs efficiently.